Simulation systems division

The activity of this division is focused on design, development, manufacturing and delivery of state of the art training simulators for power industry, especially for nuclear power plants. The development team has a long tradition of over 30 years in this field.

Simulators are designed and delivered as complex set of hardware and software parts on the turnkey basis, starting from the design phase up to the system assembly completion at the customer’s site, including training of the customer staff for simulator operation and with the long term engineering services for operation support during the system’s life.

The division provides also support and auxiliary services, e.g. long-term customer service and maintenance of these systems, their upgrade and modernization, expert assessment and evaluations, studies of different kind, including training of the user’s personnel.

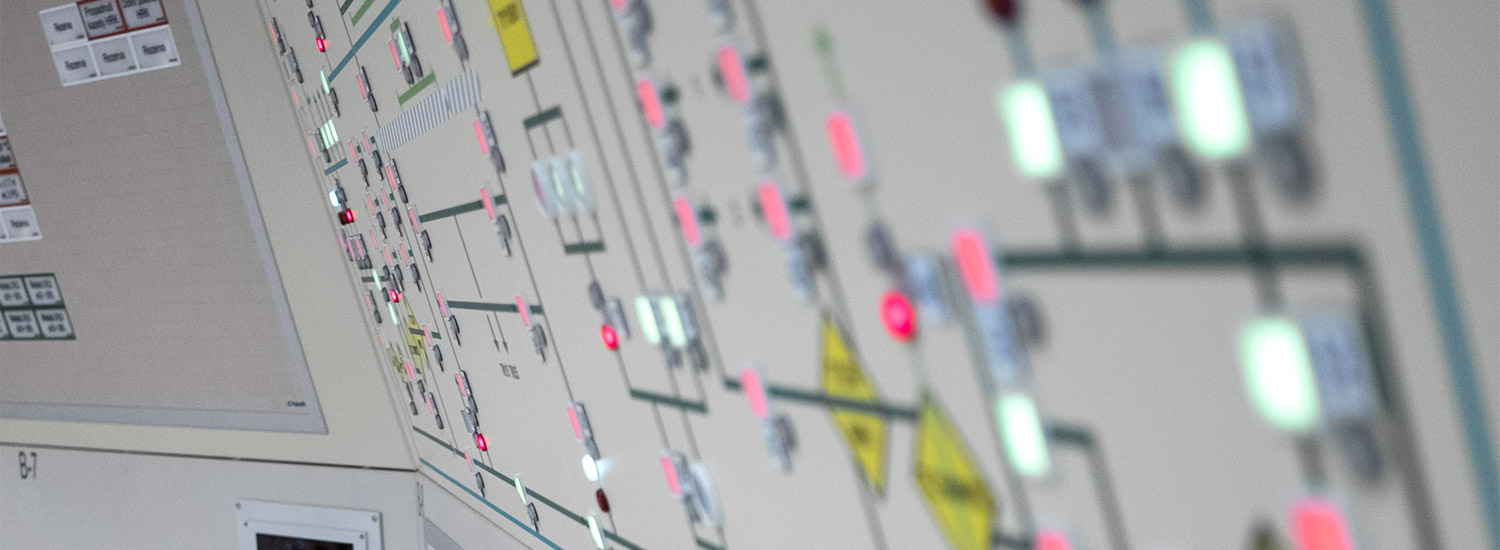

Replica-type simulator

These are, mainly, simulators of nuclear power plants simulating in real time and in great detail the function of most devices in almost full range of their operating modes and being equipped with a full realistic replica of the control room. They are designed primarily for operator training allowing to practice equipment handling under standard conditions, during non-standard situations or accidents.

Due to a high level of fidelity, scale and complexity of simulated processes as well as advanced user control and management tools, the supplied simulators are increasingly being used also to support engineering activities such as design and functional verification of large and complex control algorithms, for the verification and validation of standard, non-standard and emergency operating procedures or for tasks related to the design and validation of the GUI/HMI.

Last but not least, these simulators are also used as analytical tools to support engineering activities during commissioning of the power plant and its control system or during subsequent processes of modifications and upgrades.

Display based simulator

Display simulators differ from replica trainers by the fact that the full replica of the control room is replaced by a detailed visualization of the control panels on the graphical displays. Due to less comfortable handling, the possibilities for their use for training are somewhat limited. Like replica simulators, however, display simulators of nuclear power plants can fully simulate in real time and in detail the function of most devices in almost the full range of their operating modes, and therefore it is an effective tool for practical training of operators and operational staff.

Furthermore, display simulators are used as a very effective support for engineering activities such as design and functional verification of large and complex control algorithms, for the verification and validation of standard, non-standard and emergency operating procedures or for tasks related to the design and validation of the GUI/HMI.

Last but not least, it also serves as an analytical tool to support commissioning of the plant and its control system, as well as its modifications and upgrades.